china dredge pump casing factory

Latest articles

Submersible Slurry Pump

china dredge pump casing factory...

china dredge pump casing factory 【china dredge pump casing factory】

Read MoreLarger impellers made of more material. This is to compensate for the wear caused by abrasive slurry.

china dredge pump casing factory...

china dredge pump casing factory 【china dredge pump casing factory】

Read MoreConsider the following.

china dredge pump casing factory...

china dredge pump casing factory 【china dredge pump casing factory】

Read MoreThe winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

china dredge pump casing factory...

china dredge pump casing factory 【china dredge pump casing factory】

Read MoreWhat is the pump constructed of?

china dredge pump casing factory...

china dredge pump casing factory 【china dredge pump casing factory】

Read MoreThe impeller is considered the heart of the dredge pump and is similar to a fan that expels air and creates centrifugal suction. At the suction pipe, this vacuum absorbs the slurry and transports the material through the discharge line.

china dredge pump casing factory...

china dredge pump casing factory 【china dredge pump casing factory】

Read MoreLonger maintenance intervals

china dredge pump casing factory...

china dredge pump casing factory 【china dredge pump casing factory】

Read MoreOne of the most frequently asked questions from our team of pump experts is: How do I pump slurry?xa0With this in mind, our team of experts have provided a useful guide to pumping slurry.

china dredge pump casing factory...

china dredge pump casing factory 【china dredge pump casing factory】

Read MoreThe Mud pumps need to be equipped with auxiliary equipment, but slurry pumps not. They often need to use with high-pressure water pump when mud pump working. The high-pressure pump sent the water that larger than the mud pump pressure to the leakproof packing. Then protect the packing. Otherwise, it is easy to make the seal part wear. But the wear-resistant slurry pumps can complete the transportation work independently, which not need to equip other auxiliary equipment.

china dredge pump casing factory...

china dredge pump casing factory 【china dredge pump casing factory】

Read MoreLarger impellers made of more material. This is to compensate for the wear caused by abrasive slurry.

china dredge pump casing factory...

china dredge pump casing factory 【china dredge pump casing factory】

Read More

Popular articles

- There is a better way to pump sewage, overflows and other collected dirty water around the plant.

- Make sure you follow the basic rules of pump piping.

- What we mean by slurry is basically a liquid containing solid particles. When you want to pump this slurry, there are different requirements than when pumping only dirty water. A waste water pump cannot handle the solid particles of a slurry. This is where slurry pumps come in handy. >Slurry pumps are heavy duty and robust versions of centrifugal pumps, capable of handling tough and abrasive tasks.

- To reduce component wear, most centrifugal slurry pumps run at fairly low speeds - typically less than 1200 rpm. Find the optimum position that allows the pump to run as slowly as possible but fast enough to prevent solids from settling out of the slurry deposit and clogging the lines.

- A >dredge pump is a horizontal centrifugal pump that is the heart of a dredger. It is designed to handle suspended abrasive granular materials and solids of limited size. Without a dredge pump, a stranded dredger would not be able to deliver mud.

- - Pumping media where abrasive particles are present

Latest articles

-

Slurry Pump

-

Slurry Pump

-

Dredge Pump

-

Slurry pumps are usually larger than standard pumps, have more horsepower and use stronger bearings and shafts. The most common >type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids pass through a standard centrifugal pump.

-

For certain types of slurry pumping conditions, positive displacement pumps may be a more suitable option than centrifugal pumps.

-

3.Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear and tear caused by abrasive slurries. Slurry pumps are typically larger in size compared to low viscosity liquid pumps and often require more horsepower to operate due to their lower efficiency. Bearings and shafts must also be more robust and durable.

In conclusion, bulk bag sewing machines play a vital role in modern industrial manufacturing. With continuous advancements in technology and automation, these machines are set to become even more efficient and versatile. As industries face new challenges and opportunities, the ability to package bulk materials effectively will remain crucial, highlighting the importance of investing in high-quality bulk bag sewing machines for sustained growth and success.

One of the most significant advantages of a sewing machine with an automatic backstitch feature is the time it saves. For professionals and serious hobbyists alike, every minute counts when working on a project. The automation allows the sewist to focus more on creativity and design rather than getting bogged down in repetitive tasks. This means that complex projects, such as garments or quilts, can be completed more quickly without sacrificing quality.

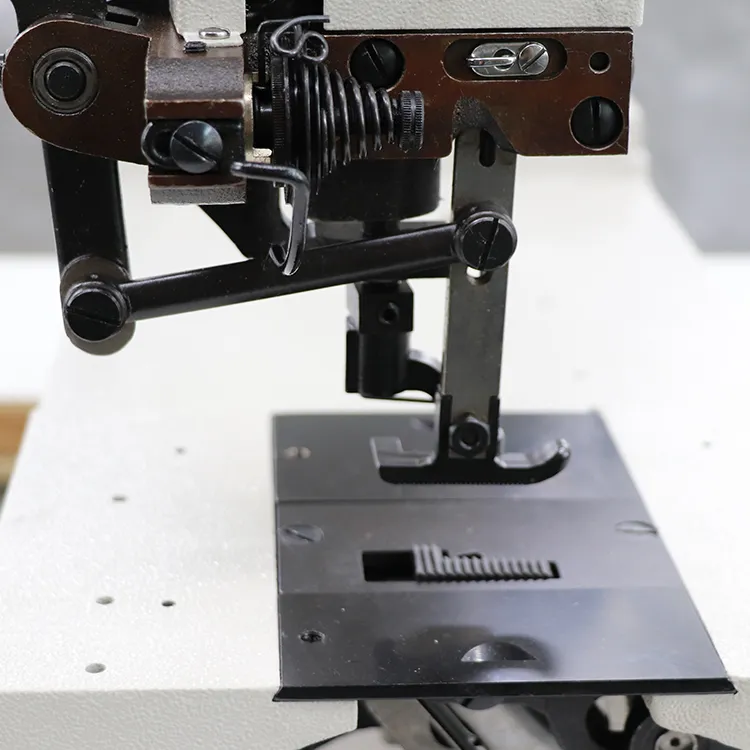

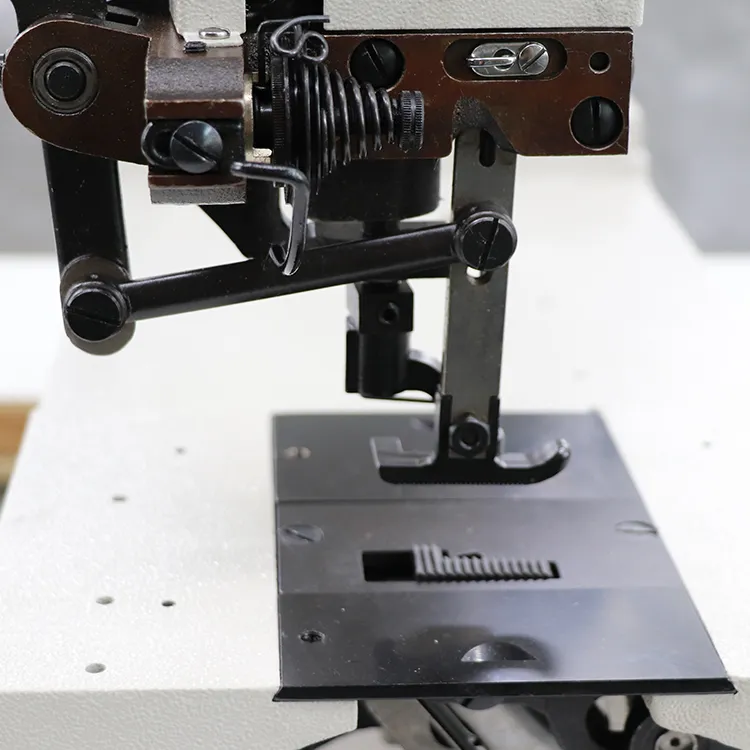

2. Smooth Operation The chrome coating allows for a smoother glide through fabric, which is especially important when working with delicate or slippery materials. This smooth operation reduces wear on both the needle and the fabric, ensuring a better finish on the project.

Benefits of Using a 3-Needle Chain Stitch Machine

2. Enhanced Durability The reinforced seams created by a double stitch machine provide extra strength, reducing the likelihood of seams unraveling over time. This quality is vital for garments that undergo intensive use, ensuring customer satisfaction and reducing return rates.

The World of Multi-Needle Quilting Machines

Despite the advancements, bulk bag sewing machines also face challenges. The need for regular maintenance and training for operators remains critical to ensure that machines run smoothly and efficiently. Additionally, factors such as fluctuating raw material prices and increasing competition require manufacturers to innovate continually and find cost-effective solutions.

lock stitch sewing machine. Whether you are working on a delicate garment or heavy-duty materials, a lockstitch sewing machine can provide the versatility and precision required for different sewing tasks.

The complexity of creating a lockstitch is facilitated by modern sewing machines, which are designed to maintain consistent tension on both threads. This is crucial; too much tension can cause the fabric to pucker, while too little can lead to loose stitches that might unravel. Therefore, understanding how to adjust the tension settings on the machine is vital for achieving a high-quality lockstitch seam.

One of the standout features of these machines is their ability to accommodate different button sizes effortlessly. Most models come equipped with a specialized attachment or sensor that determines the size of the button placed in the machine. Once the size is detected, the machine automatically adjusts its settings to sew a buttonhole that perfectly fits the button, ensuring a secure and polished finish every time.

Technique and Tools

Conclusion

Ease of Use:

While the industrial double needle sewing machine is robust and efficient, proper maintenance is crucial to ensure its longevity and optimal performance. Regular cleaning and oiling of moving parts are necessary to prevent rust and keep the machine running smoothly. Additionally, operators should inspect needles for wear and replace them promptly to avoid compromising the quality of stitches.

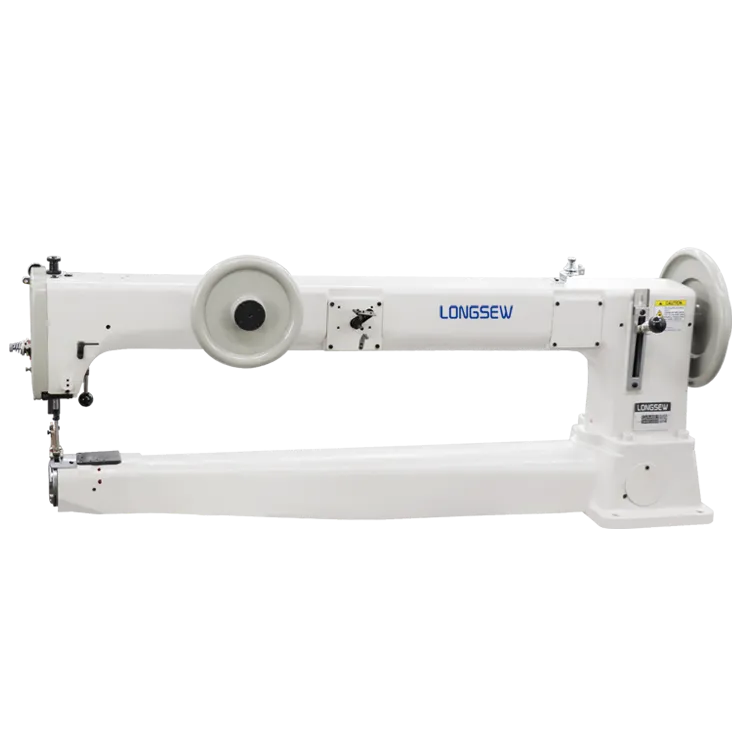

The Versatility and Benefits of Raised Bed Sewing Machines

It also excels in sewing multiple layers, piping, and appliques, providing a professional finish to various sewing projects It also excels in sewing multiple layers, piping, and appliques, providing a professional finish to various sewing projects

It also excels in sewing multiple layers, piping, and appliques, providing a professional finish to various sewing projects It also excels in sewing multiple layers, piping, and appliques, providing a professional finish to various sewing projects single needle walking foot sewing machine.

single needle walking foot sewing machine.2. Brand Reputation

Understanding the Price of Five Thread Overlock Machines

What is a Commercial Zig Zag Sewing Machine?

The Zig Zag Dressmaker Sewing Machine A Craftsperson’s Essential Tool